Building our Own 3D Printer from scratch

and what the project of recreating it aspires

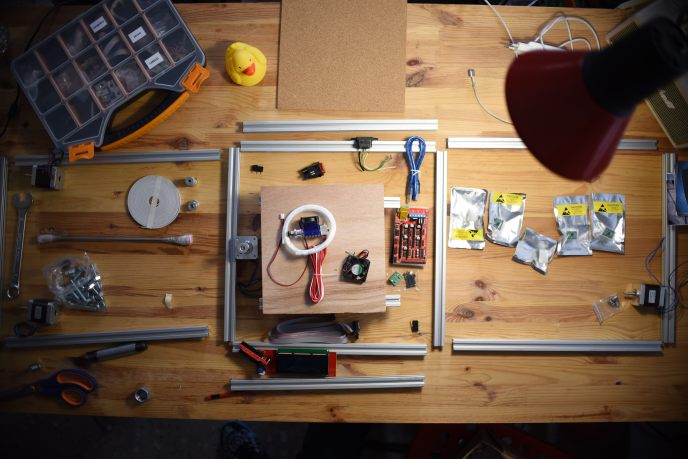

Back in 2014 my colleague Michael decided to buy a 3D printer. During his online research, the RepRap project popped up. Everything around this project was very interesting and engaging and led to his first order. Mono Mendel from a company called RepRapPro meant to be his first 3D Printer. It came in a box with instructions on how to assemble the parts.

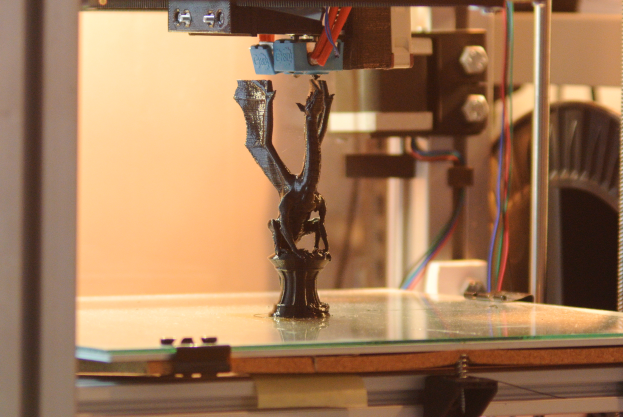

After printing a great variety of objects, both of his own design and others' posted online (for free use of course), Michael knew all the pros and cons of his Mendel. His first impulse was to improve it. But the restless creator inside him wanted to take over and do more fun stuff.

So he decided to built his own 3D Printer.

What are our goals with Rosalind no2

In the beginning of the process we asked ourselves a few questions to help us draw the guidelines that would keep us on track.

- Do we want to keep the characteristics that Rosalind already has?

- How can we fund this project sustainably?

- What new nuances does she aspire to?

The first question was an easy one. All four parameters were still important to us.

Especially remaining open source in a constantly growing entrepreneurial world. Focusing a lot on the community and on spreading the knowledge of 3D printing is deeply connected with our approach on trying to find out how things work, instead of the it just works mentality.

This is an open source project from early on, created by an active member of the open source community, who wants to continue with contributions for the community and vice versa. Create an open chat channel was recently crossed off our to do–list. You can join us at #rosalind on irc.freenode.net, where we can engage in our love for 3D printing. We'd love to read about other people's ideas and concepts, print their designs, help them with prototyping and take into consideration their proposals for improvement.

A virtual place with pictures from other creators Rosalind's prints would be awesome!

The second question needs a lot of work.

I got to be honest here. For now we only make use of affiliate links to the products we bought to build Rosalind. That's all. Apart from that we have in mind a couple more baby steps. If our project grows enough and there are people interested in building their own 3D Printer, but not sure what or where to buy their vitamins from, we could pack and ship assembly kits with all the pieces. We could also create special 3D printed items like faux jewelry or home decoration and sell them in a small store at our neighborhood or even online. But we are still far away from that.

The third question was a bit harder to answer, but we managed to sort out our thoughts.

Our new 3D Printer needs to feel tinker–friendly, repair–friendly and do–it–yourself friendly. All the way friendly!

Playfulness appears to find its place in our agenda.

We want people to get the feel of exploring and playfulness that they get from a new game. We want to connect with the inner child of the individual, who wants to explore the world of 3D printing. We do not want it to be just a game with strict instructions. We want it to be an invitation to get on the floor, and follow the steps to create a new game that, yes, we designed, but they are making. Moreover we want to give examples of toys that people can make just for fun!

Practicality is another aspect appealing to us.

We want to be able to show of things that people can print with their 3D printer that are also practical in their everyday lives. The 3D Printer is not just a machine to create junk. It is also a tool that can be added to people's lives and maybe occupations. 3D printing can be part of our life if it is easy to use.

Innovation in today's world is key.

We want to continuously create new things. Most open source 3D printers (even those created with OpenSCAD) are not parametric enough and minor modifications in size require a lot of work. We set out to create a printer which will be configurable by just editing a few files and maybe, in the short future by selecting things on a website. No, Rosalind doesn't have any fancy new extruding techniques or multiple materials (at least for now). But we aim for it to be very easily buildable, without any custom parts you can't print yourself, or purchase off the shelf.

Eco–friendly is the last aspect for now.

There is a way to make your filament from plastic bottles. This is a great opportunity to recycle, save a bit money on your supplies and print even more! We plan this as our next endeavor, but no promises!

More updates to come! Stay tuned.